|

924Board.org

Discussion Forum of 924.org

|

| View previous topic :: View next topic |

| Author |

Message |

bruni

Joined: 26 Jul 2008

Posts: 114

Location: South Africa

|

Posted: Sun Oct 26, 2008 9:57 pm Post subject: Who has water injection Posted: Sun Oct 26, 2008 9:57 pm Post subject: Who has water injection |

|

|

Who has water/methanol injection? what do you think of it, which make or home brew, what are your views on nozzle placement any other comments ?

_________________

1982 931

1975 harley sportster |

|

| Back to top |

|

|

ideola

Joined: 01 Oct 2004

Posts: 15548

Location: Spring Lake MI

|

Posted: Mon Oct 27, 2008 3:10 am Post subject: Posted: Mon Oct 27, 2008 3:10 am Post subject: |

|

|

tuurbo has one from Snow (I think) and Smoothie has a home built version. Lots of posts covering this topic if you search

_________________

erstwhile owner of just about every 924 variant ever made |

|

| Back to top |

|

|

tuurbo

Joined: 08 Aug 2007

Posts: 1446

Location: East Windsor, New Jersey

|

Posted: Mon Oct 27, 2008 8:09 am Post subject: Posted: Mon Oct 27, 2008 8:09 am Post subject: |

|

|

Hi Bruni, Ideola, yes I have a Snow system that puts in about 120 ml/min using two 60 ml/min nozzles, one before the turbo, from the airbox straight into the CIS, and one about 5" from the throttle in the aluminum charge tube. They spray a pretty spectacular, strong burst of mist. It's something one should show a cat, at a distance, just for amusement. The pumps are plentiful so easy to replace.

I use two very fine nozzles to achieve peak atomization. I was unsure of how important atomization was in the equation and took a guess that more was better. So far it's been exceptional.

I have used 90% alcohol 10% distilled water when I've wanted to richen the mix, and have settled on 50% mix now because it is more important to me that I cool the charge. Germany used to have MW50 which contained a few drops of oil.

Unfortunately, I was getting detonation quite early on in the boost phase. I think that it's because the head was reconditioned and shaved. I was getting ping at <1 PSI of boost. Since installing the boost switch properly I've eliminated the ping. The downside is that I use a bit more juice because the pump comes on at <1 PSI. I think I get around 3-5 tanks of gas before I replace the gallon or so (7 litres?) of boost juice. You can feel the car runs like it's intercooled from the moment the boost comes on right up to 10+ PSI.

The next situation, which I'm doing now that the car is off the road, is a second stage of boost juice to kick on at 7 PSI through to 12 PSI. I have a solenoid I can switch on at 7 PSI and run the second 60 ml injector, or a third. I can see room on that aluminum pipe to have four nozzles, if someone wanted it. Two should be enough for me.

I'm sourcing nozzle fittings right now so that I can use maybe a metal hose/plumbing in the engine bay.

The ideal situation is a progressive controller. It can be used with the existing car, or I suppose hooked up to Megasquirt. One of the guys here, I think Min, and others too suggested that you could squirt in methanol and distilled water and even tune it with MS. I think you could get some impressive changes in EGT. For me, I can't do MS right now, but something I'm drawing out in my mind is how one can use individual 'tunnels' with four injector nozzles to spray in with the air directly above the head, without modifying the head. I just don't know right now how I could benefit from doing so without the kind of precise timing you'd get from EFI and electronic injectors.

One thing I've been wondering is this: Does it even make sense to use IAT to measure the effectiveness of methanol and water injection? How do you know you're not measuring the temperature of the liquid medium? Don't EGT measures or O2 signals tell you useful things about how your system is working?

_________________

1980 924 turbo, MSD, Meth. Inj, otherwise stock. |

|

| Back to top |

|

|

bruni

Joined: 26 Jul 2008

Posts: 114

Location: South Africa

|

Posted: Mon Oct 27, 2008 10:29 am Post subject: Posted: Mon Oct 27, 2008 10:29 am Post subject: |

|

|

Hi thanks for that, all good information, I want to fit a system to my 82 turbo which is standard as far as i am aware, however it does ping slightly on full throttle so I intend to fit water injection. I know what you mean about the AIT sensor, however provided it is not directly in the path of the spray nozzle it should be OK. an EGT sensor is a really useful tool but not necessarily on its own, a good indicator of AIT as I believe it is more directly affected by mixture and timing. In an ideal world I would have AIT, EGT, and O2 sensors ++++ but hey I live in the real world

_________________

1982 931

1975 harley sportster |

|

| Back to top |

|

|

alexvex

Joined: 31 Jul 2006

Posts: 420

Location: Seattle, WA (from Indiana)

|

Posted: Mon Oct 27, 2008 10:59 pm Post subject: Posted: Mon Oct 27, 2008 10:59 pm Post subject: |

|

|

I've got a coolingmist setup that's going on this week...

_________________

--Alex--

1992 Porsche 968 (VW 2.5L I5 Turbo swap in the works)

1995 Audi 90 Quattro Sport (4.2L V8 Swap)

2010 Touareg TDI

Past Pcars: 80 931, 87 924S, 87 951 |

|

| Back to top |

|

|

Scorpio

Joined: 05 Jul 2007

Posts: 1957

Location: Brisbane, Australia

|

Posted: Tue Oct 28, 2008 9:04 pm Post subject: Posted: Tue Oct 28, 2008 9:04 pm Post subject: |

|

|

tuurbo you are the water injection king!

_________________

1979 NA

MS1..EFI..

GARRETT T25 TURBO

BILSTEIN SHOCKS

GT BASED CUSTOM BODYKIT

Brisbane , Australia

Think mean think fast

all youll see is

my Porsches Arse!!! |

|

| Back to top |

|

|

tuurbo

Joined: 08 Aug 2007

Posts: 1446

Location: East Windsor, New Jersey

|

Posted: Wed Oct 29, 2008 1:08 am Post subject: Posted: Wed Oct 29, 2008 1:08 am Post subject: |

|

|

lol I'm totally a fan of water and methanol injection Scorp. It's doing everything I'd want an intercooler to do.

Here are some articles I'm using to do a write up on water and methanol injection.

The jump page:

http://www.wwiiaircraftperformance.org/

Detailed Reports on Water Injection

http://www.wwiiaircraftperformance.org/f4f/fm-2-16169.pdf

http://www.wwiiaircraftperformance.org/f4u/kd227.pdf

The R2800 Double Wasp, ThunderBolt, P47, Hellcat, FW-190A, Messerschmitt (e.g., performance improvement was about 10% or 200 HP) and Corsair all used it. Finally, the P-51H was the finest US fighter during the war and it used water injection. I'm sure they needed reliability in battle. So I'm confident of the numbers that came out during that time.

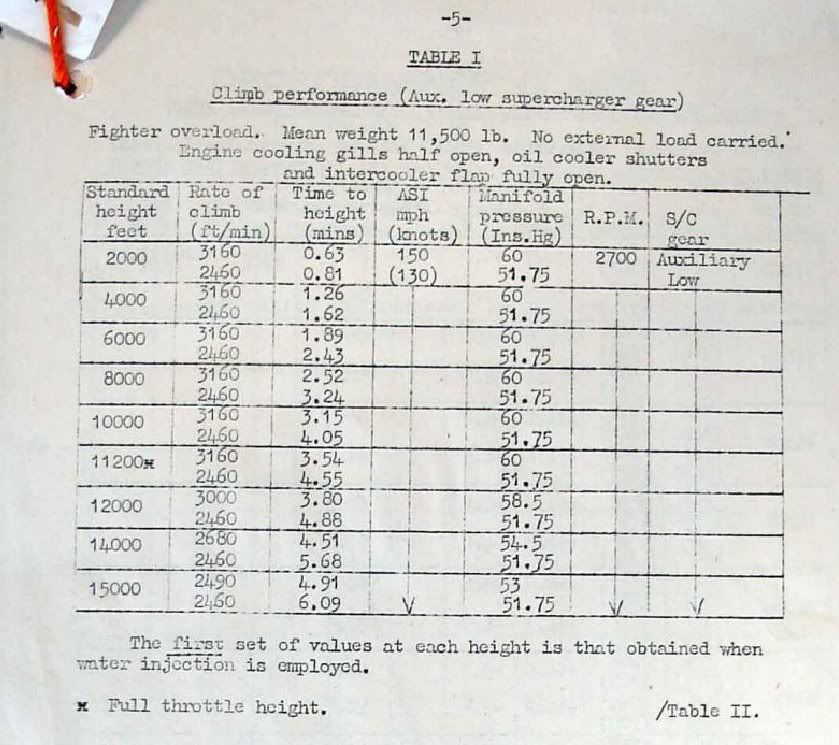

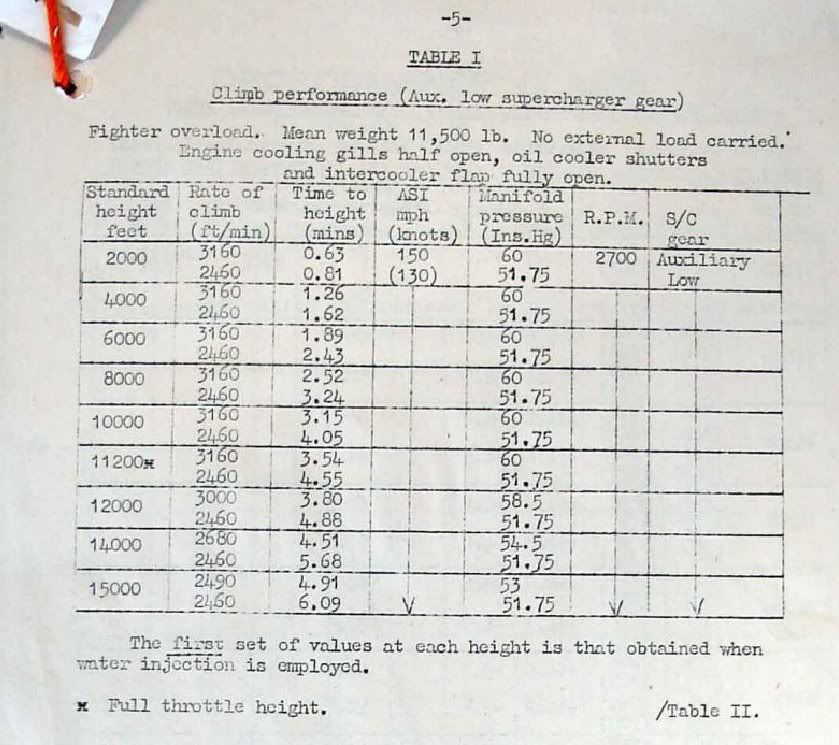

The following shows two figures in each cell. The first set of values in each cell is when water injection is used. Note too that these tests were done using aircraft equipped with intercoolers - it seems they found benefits by using water injection even with an intercooler, and note too that they're not using methanol.

Note that the Time to Climb Height is fully 1 minute earlier at 15,000 ft which would give American pilots a huge gain over aircraft with no water injection. Once you're up higher, you're in a position to attack.

It was also used on commercial aircraft, which is interesting because it's an environment where reliability and timeliness is also very important.

My wife's father worked on the P47 in Europe.

_________________

1980 924 turbo, MSD, Meth. Inj, otherwise stock. |

|

| Back to top |

|

|

bruni

Joined: 26 Jul 2008

Posts: 114

Location: South Africa

|

Posted: Wed Oct 29, 2008 2:41 am Post subject: Posted: Wed Oct 29, 2008 2:41 am Post subject: |

|

|

Wow what fantastic documents

_________________

1982 931

1975 harley sportster |

|

| Back to top |

|

|

ideola

Joined: 01 Oct 2004

Posts: 15548

Location: Spring Lake MI

|

|

| Back to top |

|

|

ideola

Joined: 01 Oct 2004

Posts: 15548

Location: Spring Lake MI

|

Posted: Thu Oct 30, 2008 12:41 am Post subject: Posted: Thu Oct 30, 2008 12:41 am Post subject: |

|

|

tuurbo, one question that occurs to me about the use of water-alcohol mix is whether the alcohol can cause any detrimental affects to the stock system due to its corrosive nature. Granted, most of the sensitive components are in the fuel delivery system which would be upstream of the water/alc injection point...just a passing thought...

_________________

erstwhile owner of just about every 924 variant ever made |

|

| Back to top |

|

|

tuurbo

Joined: 08 Aug 2007

Posts: 1446

Location: East Windsor, New Jersey

|

Posted: Thu Oct 30, 2008 4:07 am Post subject: Posted: Thu Oct 30, 2008 4:07 am Post subject: |

|

|

| Quote: | | tuurbo, one question that occurs to me about the use of water-alcohol mix is whether the alcohol can cause any detrimental affects to the stock system due to its corrosive nature. Granted, most of the sensitive components are in the fuel delivery system which would be upstream of the water/alc injection point...just a passing thought... |

It's a good passing thought. The Germans used MW 50 during WWII which contained 0.5% Schutzöl 39 as an anti corrosion additive. I have used tranny fluid, just a teaspoon. Also, there's some evidence that the use of MW50 by the Germans resulted in some aircraft having cracked heads. I was worried when I first read about this issue. After all, methanol will also corrode aluminum.

I was comforted when I found out the new Dodge Hemi V8 engine with an aluminum head is designed to run on E85. Add to this the fact that the alcohol series drag racers use aluminum heads and I think it's safe to assume that any aluminum head degradation that happens is probably going to be insignificant. We don't dump very much methanol into the system when we're using methanol injection. And the exposure time is less than a second. However, I think running E85 gas through your tank and pump is a different story.

I've experimented with a few plastics and rubbers by immersing these in pure methanol for a few days at a stretch. The plastics I used were severely degraded by the methanol mix, and would crack quite easily with just a little pressure. The rubber pieces I tested were not degraded when I tried bending them, but I'm unsure whether they were pure rubber, or polypropylene, or what. I also stretched them but didn't really have a way to know whether I was stretching them enough to see an effect.

I've taken two samples of 3.6 mm ID rubber air lines and two samples of 13 mm ID rubber hoses (the kind with nylon threads). I'll immerse them for 24 hours straight, which should give us some idea of what happens with methanol and rubber. I believe these rubber pieces handle air but it might be useful to know how they'll react.

If you place the nozzles in the intake charge tube, there's a possibility for corrosion of the large black plastic connecting piece at the throttle-charge tube connection. But the amount of plastic that's actually exposed shouldn't be more than 1/2". Also, cork gaskets may be problematic.

Here's what a methanol E85 website says:

"One possible complaint against methanol as a blender that arose in the 1930's, was that methanol was corrosive to certain materials in a car's fuel system. At the same time, carburetor floats made of cork, and gaskets sealed with shellac, were easy game for alcohol. Present metal floats and synthetic cements resist the solvent action of alcohol. Carburetor parts are made of zinc die castings, sometimes aluminum. The impurities in those early day metals were conducive to "inter-granular crystallization" as a result of aging. This crumbing destruction could be accelerated by the presence of alcohol and water, but the problem no longer exists in todays version of those metals. Lead, tin and magnesium are attacked by methanol, but there should be no opportunity of exposure to these metals in the combustion zones of an engine. Iron and steel are quite immune, as are brass and bronze.

Users of pure methanol found an unsuspected cause of trouble in the gasoline tank, which traditionally has been made of "terne plate," a favorite roofing material of Victorian architects. It is steel sheet coated with lead, making it ideal for resisting rust from water in gas tanks. Methanol reacts with lead, slowly but surely, forming a flaky sludge that plugs filters in the fuel system. The easiest solution is to inspect and clean the filters every few days while using methanol fuel. The lead should all be eliminated within a couple of weeks of usage."

I think it's still a relatively open question as to whether or not methanol is absolutely safe for the 931. I think if degradation happens, it hasn't happened yet (or it has gone unnoticed) to those of us that have been running it.

Results

After 24 hours the small and large hose sizes compress with slightly more effort. It's as if the rubber has 'cured' to a stronger piece. Bent the tube 180 degrees and no cracking. Kept the dishes covered to prevent evaporation.

_________________

1980 924 turbo, MSD, Meth. Inj, otherwise stock.

Last edited by tuurbo on Fri Oct 31, 2008 6:33 am; edited 1 time in total |

|

| Back to top |

|

|

ideola

Joined: 01 Oct 2004

Posts: 15548

Location: Spring Lake MI

|

Posted: Thu Oct 30, 2008 4:23 am Post subject: Posted: Thu Oct 30, 2008 4:23 am Post subject: |

|

|

Be careful about your assumptions re: old aluminum heads. From my research on E85, all manufacturers have been required by federal law (and the laws of physics) to formulate and treat aluminum engine components so that they are safe with Ethanol-mixed fuels since ... (and here's the key) ... the early 1990s. Our late 70s designed engine components have no such treatment, so the concern over prolonged exposure to any type of alcohol is real. Treatments include flavors of nitriding, anodizing, and powder coating.

Now, having said that, Ethanol is not nearly as corrosive as Methanol (by at least an order of magnitude). Based on what I've seen, Methanol has been proven to be highly corrosive to untreated aluminum. God only knows what grade aluminum is used in our heads and intake tracts. I don't mean to be a fear monger, because I don't know, I can only report on what I've researched. Personally, it gives me pause to think about spraying methanol into the untreated early interior of our intake manifolds. The corrosion, by the way, causes microscopic degradation of the aluminum, which creates issues for both pollution and contamination of the fuel.

As for rubber and nitrile and other components. This is a significant concern. I am convinced that no fuel system should be blindly converted over to ANY concentration of Ethanol (let alone Alcohol or Methanol) without addressing it from head-to-toe. That means from the tank all the way to the combustion chamber. The biggest concern is that the stock rubber seals and the stock rubber and nitrile lines from the fuel pump, within the CIS components, and the fuel injector lines WILL degrade MUCH faster when exposed to higher concentrations of Ethanol, much less more aggressive forms.

I was even contacted by a board member here who works for Shell R&D in the UK and has had significant challenges sourcing components that were compatible with BOTH regular pump gas and ethanol-based mixtures. As I shared with him:

| ideola wrote: | I just happened across an article this evening in the Oct 2008 issue of Racecar Engineering magazine, page 8, that discusses new seals that have been developed and released by Stäubli (http://www.staubli.com). According to the article, these seals were developed to replace conventional Viton seals, specifically for race cars that are increasingly demanding bio fuel alternatives. To quote the article:

"To accommodate the new fuels successfully, Staubli has introduced an upgraded range of seals based on perfluoroelastomer material. Connectors with this type of seal are marked JKV and are suitable for all types of fuel, including bio-fuel in concentrations from 10%-85%." |

Of course, the problem is finding any real quantifiable test data. I think water injection is just fine. I don't think I would want to run Methanol in my engine after everything I've read. YMMV. In any event, I am heading squarely down the E85 path for my UWB project. Should provide interesting R&D for other developments...like how about a E85 931 running the UT-CIS?! I've already contacted Unwired Tools, and it is a definitely possibility. Bwahahahahah!

_________________

erstwhile owner of just about every 924 variant ever made |

|

| Back to top |

|

|

tuurbo

Joined: 08 Aug 2007

Posts: 1446

Location: East Windsor, New Jersey

|

Posted: Thu Oct 30, 2008 6:29 am Post subject: Posted: Thu Oct 30, 2008 6:29 am Post subject: |

|

|

Carefulness regarding the assumptions is an issue when using methanol and water injection, just as it is an issue when rejecting the use of methanol and water injection, or supposing that it harms the head or intake.

Have you found any evidence of methanol-water injection ruining someone's aluminum head?

If so, I'll listen.

I haven't yet found evidence of methanol and water injection resulting in aluminum head damage on aircraft or automobiles. Remember, the following are production numbers for each aircraft:

1. P-47C - 57+55+128, nearly 200 aircraft, with no reports of head problems due to methanol injection.

2. Rolls Royce Dart engine in production from 1950 through to 1987 in the following aircraft, without aluminum degradation:

* Armstrong Whitworth AW.660 Argosy medium-range transport (C Mk 1 variant)

* Avro 748 Feeder airliner

* Grumman Gulfstream I Executive/Passenger aircraft

* Breguet Alizé anti-submarine aircraft: Dart RDa 21 1950hp with water/methanol injection

* Fokker F.27 small airliner

* Handley Page Dart Herald small airliner

* Hawker Siddeley Andover military transport

* NAMC YS-11 short/medium range airliner (Japanese Aircraft)

* Some Douglas DC-3 transport aircraft have been upgraded to use Darts. DC-3's in BEA service which received this update were called Pionairs.

3. Rolls Royce Merlin and Griffon - The Merlin used aluminum heads, water jacket, crankcase, the Griffon used an aluminum crankcase, cylinder banks and heads. All made since 1950. Here's the breakdown for the Merlin, for example:

Model V-1650-9

Application All models:

Engine Type V-12 Piston Aero Engine, 60° "V" (angle between banks)

Material Aluminum heads, water jacket, crankcase; Steel cylinder liners; Forged aluminum alloy pistons

Bore x Stroke 5.4" x 6.0"

Compression Ratio 6.00:1

Supercharger type Two stage engine driven supercharger, 12.0" first stage, 10.1" second stage

Supercharger Ratio 6.391 (low blower), 8.095 (high blower)

Anti-detonation 50:50 water-methanol injection anti-detonation injection (ADI)

Fuel System Bendix-Stromberg PD18, Type G-9 pump, 9 psi idling, 12-16 psi operating

Weight 1,690 lbs

Power 1735 bhp @ 3000 rpm 66" boost

Rotation: CCW crankshaft rotation when viewed from supercharger end

Cylinder ID Bank: Right - A, Left - B when viewed from supercharger; "A" has oil regulator; 1-propeller end, 6-supercharger end

Firing Order 1A-6B-4A-3B-2A-5B-6A-1B-3A-4B-5A-2B,

Spark Plug 14mm thread, 0.011-0.014" gap

Magneto BTH C6SE12S/2 (Ex: AN SF 12RG-P-3 or SF 12RA-P-3, In: AN SF 12 LG-P-3 or SF 12LA-P-3)

Northeast (Ex: AN SF 12RA-P-4, In: AN SF 12LA-P-4)

Magneto Direction Exhaust Side -- CW, Intake Side -- CCW, viewed from driving end

Spark timing Fully Advanced: Intake 45° btc, Exhaust 50° btc, Magneto breaker gap 0.011-0.014

Cam Timing

(crank degrees) Intake: Valve opens 31° BTDC, Closes 52° ABDC, 0.015" clearance (cold), 0.590" max lift -- Note: Time w/0.020

Exhaust: Valve opens 72° BBDC, Closes 12° ATDC, 0.020" clearance (cold), 0.590" max lift

263° intake duration, 264° exhaust duration

Note: Tappet clearance for timing -- 0.020"

If you add water to methanol, you have the oxygen required, I should think, for re-oxidization to happen. Even 1% could be enough. I run 50:50.

I'm willing to entertain thoughts of methanol screwing up the aluminum in my 1980 Porsche 931, but I'll worry when I see an empirical case of it.

_________________

1980 924 turbo, MSD, Meth. Inj, otherwise stock.

Last edited by tuurbo on Thu Oct 30, 2008 6:57 am; edited 1 time in total |

|

| Back to top |

|

|

ideola

Joined: 01 Oct 2004

Posts: 15548

Location: Spring Lake MI

|

Posted: Thu Oct 30, 2008 6:42 am Post subject: Posted: Thu Oct 30, 2008 6:42 am Post subject: |

|

|

First, just because one aluminum-based motor used it safely means nothing, unless you have empirical information detailing the grade of aluminum used and any special treatment was given to those materials.

Second, in the absence of empirical evidence, we can make inferences based on what OEM manufacturers are doing. The fact that ALL major OEMs changed their manufacturing process around aluminum-based engines in the early 90s specifically because of the concerns over Ethanol-induced corrosion is enough of a reason to be concerned in my opinion. Multiply that by whatever order of magnitude you want for the increased corrosiveness of Methanol over Ethanol.

Third, yes, I have found empirical evidence of problems systems not designed for Ethanol based fuels. Do some poking around at this site: http://icorr.net/papers.html

While I didn't find anything specific to an aluminum head, this is one of the few sites I found that actually cited scientific studies vs. the usual fear-mongering found on discussion forums.

Bear in mind, Methanol is more aggressive than Ethanol. I'm not a chemist, so the nuances of the impact of water mixtures and whatnot escapes me. But I do know that one of the big concerns over any Ethanol based fuel is its hydroscopic nature, which actually increases the rate corrosion.

_________________

erstwhile owner of just about every 924 variant ever made |

|

| Back to top |

|

|

tuurbo

Joined: 08 Aug 2007

Posts: 1446

Location: East Windsor, New Jersey

|

Posted: Thu Oct 30, 2008 7:12 am Post subject: Posted: Thu Oct 30, 2008 7:12 am Post subject: |

|

|

Yes but Dan, the Merlin is a WWII engine. You said clearly:

| Quote: | | From my research on E85, all manufacturers have been required by federal law (and the laws of physics) to formulate and treat aluminum engine components so that they are safe with Ethanol-mixed fuels since ... (and here's the key) ... the early 1990s. Our late 70s designed engine components have no such treatment, so the concern over prolonged exposure to any type of alcohol is real. Treatments include flavors of nitriding, anodizing, and powder coating. |

So you told me above "you can't make inferences about old aluminum based on what new engine manufacturers are doing" so I showed you the Merlin, built before WWII.

I don't want to search. I've searched to my heart's content. I'm an intelligent man old enough to know better than to install something silly on my car. Well, almost - I did consider a few silly options, but I learned. And I am careful about stuff that'll bust my car. I've seen MW50 used on aluminum head V8's from the 60's on upward to 1990's. Methanol and it's variants are used in top dragster categories for years. So I'm relatively satisfied. Is it possible I'm wrong? Sure, but I have to ask you for reasons to believe I should be concerned. The reasons that matter in this case, since we're not chemists or metallurgists, are empirical ones showing degradation on our early (or earlier) heads.

Remember, it's you that's making the claim that the 931 might be harmed by methanol and water injection, therefore it is your responsibility to prove your case, not mine. That's how case making works in science anyway and we've got to be scientific about our inferences.

I've glossed the articles you cite and can't see applicability to methanol and water injection (both please) cracking aluminum Porsche heads. Besides, I don't have the expertise to evaluate the controls used in those studies and I dare say, neither do you. If you do, please elucidate the finding which proves my car's aluminum components will deteriorate with a 50:50 mix of methanol and water.

Show me the degradation on the head and I promise I'll uninstall my methanol this evening. Else, I'm not moving from my couch. My car is working terribly well and so are the cars of a few buddies of mine who also use methanol.

Since neither of us has the expertise to compare grades of aluminum or castings, I suggest we stick to aluminum used prior to our own 1980s cars and make intelligent inferences from there on. I can't argue the chemistry of metals with you. I'm aware that methanol takes off the oxidation from the aluminum, but I'm content that the degradation is minimal with water being exploded with tons of oxygen around the cylinder chamber.

_________________

1980 924 turbo, MSD, Meth. Inj, otherwise stock. |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|